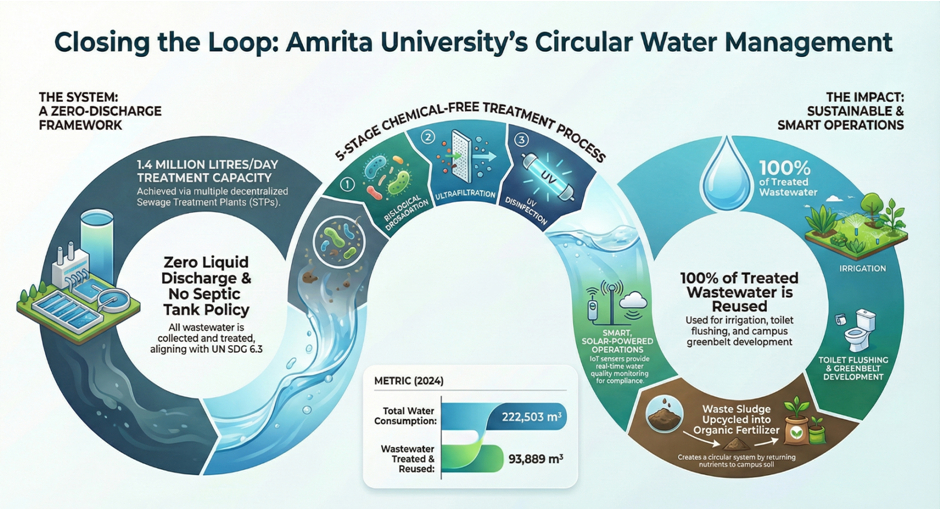

Amrita Vishwa Vidyapeetham has a comprehensive and operational wastewater treatment system in place across all its campuses, aligned with the United Nations Sustainable Development Goal 6: Clean Water and Sanitation. The university follows a Zero Liquid Discharge (ZLD) and No Septic Tank policy, ensuring that all wastewater generated on campus is collected, treated, and safely reused. This directly fulfils SDG Target 6.3.1, which focuses on improving water quality through wastewater treatment, pollution reduction, and increased recycling and safe reuse.

Amrita Vishwa Vidyapeetham operates dedicated Sewage Treatment Plants (STPs) across its campuses to treat wastewater generated from academic, residential, and healthcare facilities. The university operates multiple decentralized STPs with a combined treatment capacity of 1.4 million liters per day (MLD). These systems are designed to handle domestic wastewater from academic buildings, hostels, hospital facilities, and common utilities. Treated wastewater is reused for non-potable applications such as landscaping and flushing, with any surplus safely discharged in compliance with applicable environmental regulations.

The treatment systems use chemical-free, biological processes to ensure safe, efficient, and environmentally responsible wastewater management.

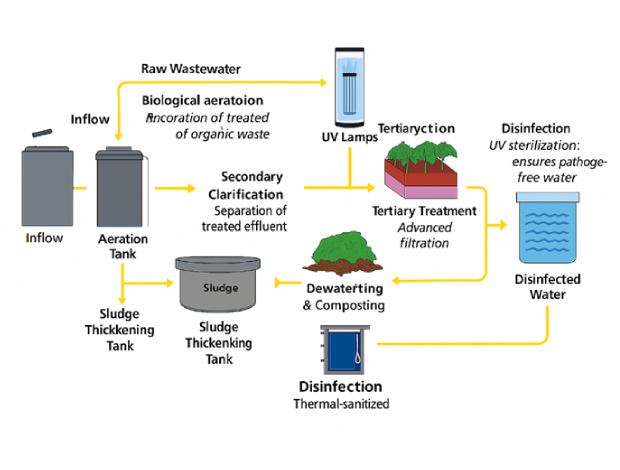

Each STP follows a multi-stage treatment process to achieve consistent and high-quality effluent:

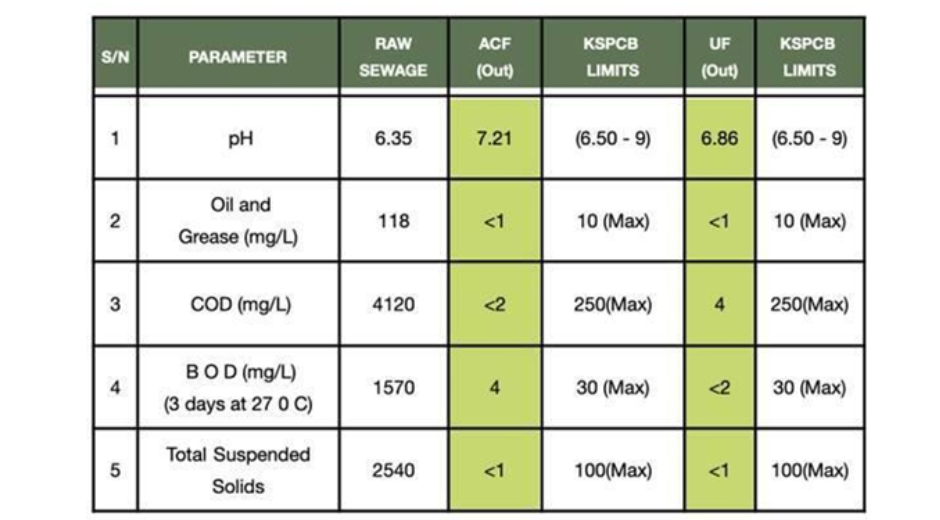

This integrated process ensures that treated wastewater consistently meets, and often exceeds, CPCB and SPCB effluent quality standards.

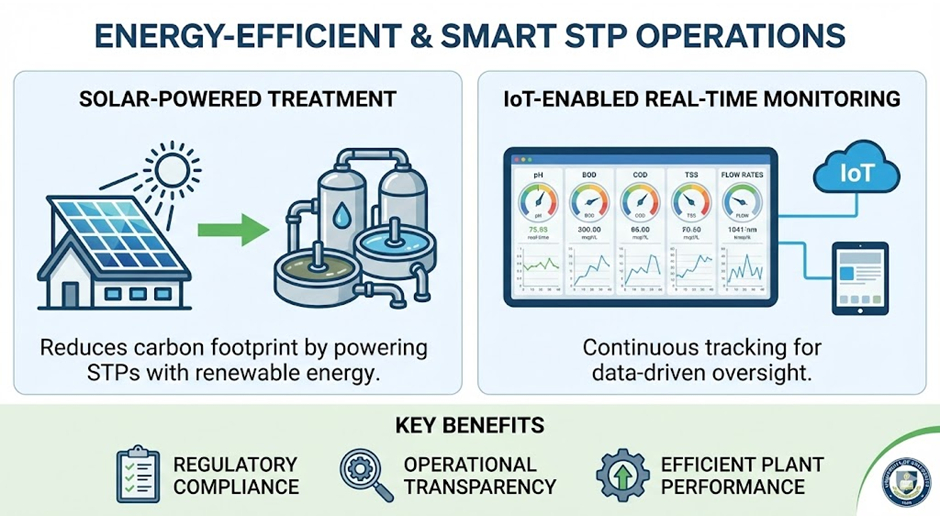

Several STPs are partially or fully powered by solar energy, reducing the carbon footprint of wastewater treatment. The entire treatment process is supported by IoT-enabled monitoring systems, allowing real-time tracking of critical parameters such as:

This digital oversight ensures regulatory compliance, operational transparency, and efficient plant performance.

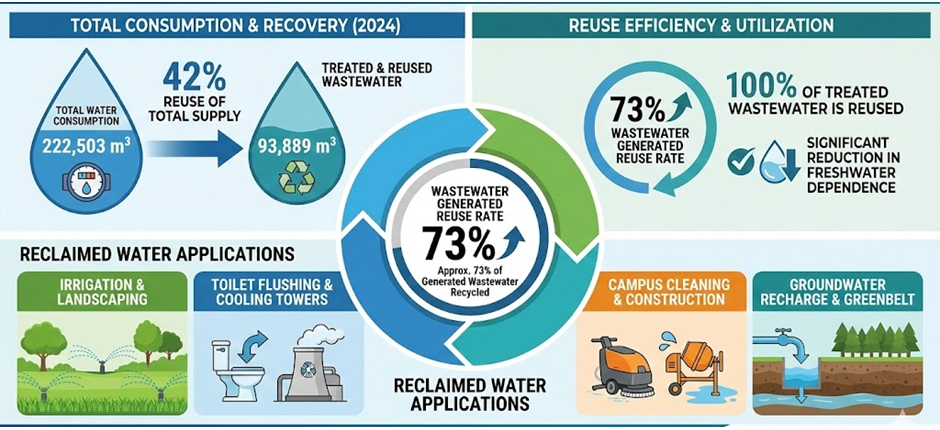

In 2024, Amrita recorded a total water consumption of 222,503 m³, of which 93,889 m³ was treated and reused wastewater. Approximately 73% of the wastewater generated was successfully treated and recycled for non-potable applications.

Reclaimed water is reused for:

As a result, 100% of treated wastewater is reused, significantly reducing dependence on freshwater sources.

Biological sludge generated during treatment is further processed through thickening, dewatering, composting, and thermal disinfection. The resulting nutrient-rich compost, containing Nitrogen, Phosphorus, and Potassium (NPK), is reused as organic fertiliser across campus landscapes and herbal gardens. This approach creates a circular water and nutrient management system, minimising waste and supporting soil health.

Treated wastewater quality is routinely monitored through:

All treated effluent complies with standards prescribed under the Environmental (Protection) Act, 1986, and meets Central and State Pollution Control Board (CPCB/SPCB) norms for sewage treatment plants.

Wastewater management at Amrita is integrated with its Integrated Water Resource Plan (IWRP), combining treatment, rainwater harvesting, greywater segregation, and innovations developed through Live-in-Labs®.

To support future growth, a new 400 m³/day Sewage Treatment Plant (STP IV) is planned for commissioning in 2025–26, further strengthening treatment capacity and system resilience.

Through decentralised wastewater treatment, zero liquid discharge, high reuse efficiency, smart monitoring, and strict regulatory compliance, Amrita Vishwa Vidyapeetham demonstrates a fully operational and sustainable wastewater treatment process, directly contributing to SDG 6.3: Improving Water Quality and Wastewater Management.